Custom Labeling Solutions for Modern Businesses – Accuracy and Efficiency with Seamless Integration

Today’s industrial, service, and infrastructure companies face an increasing need to ensure precise and traceable labeling of assets, equipment, and safety gear. It’s not just about reliable labels — companies also need solutions that integrate smoothly into their existing workflows and software systems.

Integrated Labeling – A Solution Tailored to Your Workflow

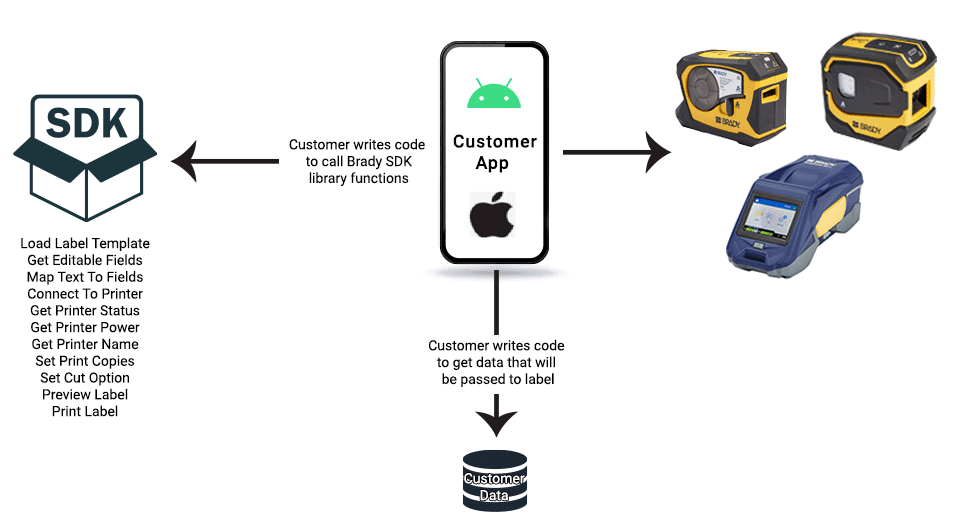

Every organization has unique operations and processes. That’s why it’s essential to offer labeling solutions that can be connected directly to a company’s existing maintenance or management software. Thanks to SDK-based (Software Development Kit) customization, it’s now possible to:

create and print labels directly from the software already in use, without the need to learn new tools;

use pre-designed templates where data fields (such as serial numbers, dates, usage info) auto-populate from the company’s database;

add barcodes, QR codes, or illustrations automatically;

print a full series of labels in one go — for example, 50 inspection tags for safety equipment, each with a unique serial number.

This approach minimizes error risk, streamlines workflows, and ensures consistent, accurate documentation.

Case Study: Labeling in Railway Infrastructure

A great example of such a tailored solution comes from a national railway company in Europe. Their goal was to enable accurate and traceable labeling across thousands of kilometers of infrastructure components. Maintenance teams needed to clearly mark which equipment had been inspected or serviced — quickly and reliably.

Using SDK integration, portable printers were connected directly to the company’s maintenance software. This allowed technicians to generate and print labels directly from the familiar user interface. The result was faster, more accurate labeling without manual data entry. The labels were designed to withstand extreme conditions typical in railway environments — including UV exposure, vibration, solvents, and oils — and adhered securely to a variety of surfaces such as metal, plastic, and wood.

Technical Advantages

Portable printer solutions offer a range of practical benefits:

Automatic calibration that saves time and materials (no label waste during setup);

Fast and easy material switching to suit changing needs;

Exceptional label durability in harsh conditions, regardless of the industry.

Partnership for the Future

These solutions go beyond simply providing a printer. They’re based on collaboration — where we, as solution providers, work closely with each company to ensure a perfect fit for their specific processes and requirements. As a result, labeling becomes an integrated, efficient, and reliable part of the organization’s daily operations.