Choosing the right labelling software

Let’s start by explaining that there’s no such thing as the „right“ software. People have different needs and taste. Also, there are a lot of aspects that influence the choice: habits, expectations, user experience or even price.

So, how to make the process of choosing label software easier?

Sometimes it’s easiest to categorize software by price. There are four basic price groups:

- Free

- Up to ~500 €

- ~1000 €

- ~2000 € and more.

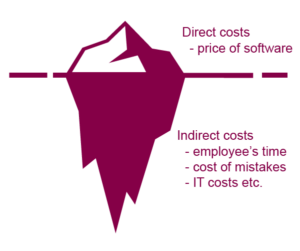

Although it seems easiest to select the label software by price, it is not the best approach, because the capability of the chosen software may not meet the expectations later. In addition, the cheaper software can turn out to be more expensive in the long run, considering the indirect costs (workers’ time, mistakes etc.).

Identifying the exact needs is a much better approach. To do this, it is worth considering the following questions:

- From how many computers and to how many printers is the printing done?

- What kind of information goes on the label? Is it only static texts/images or do you need dynamic information, for example sequences, different barcodes etc?

- Where does the information come from? Is it filled in manually each time or is it imported from Excel, some database or even automatically from the ERP system?

- Do you need to “lock” the label for the user to avoid mistakes or is it necessary to allow the user to change everything at any time?

- Does the user need to intervene (and how much) or should the printing be fully automatic?

- Is there a risk that your needs and expectations will change drastically in the near future?

When you have answered all these questions, then you have filtered out only the label software that meets the real needs. For example, if you want to print from more than one computer, then you need to either purchace multiple licences or choose a software with printer-based licencing (BarTender, NiceLabel). This allows you to print from any number of computers, but only to certain number of printers.

If the information on the labels stays the same (company name, logo, address) or the user updates the information manually each time, then a free software (BarTender Free, Brady Workstation Lite, Cablabel Lite, Zebradesigner) might be just enough. However, other restrictions must be taken into account. For example, the software may be bound to a certain printer manufacturer (Brady, Cab, Zebra) and printing to other printers is not possible. Plus, in free software, the number of different barcode types is usually limited.

Labelling software price is generally a one time fee, but employee’s time is a running cost. Therefore, it must be assessed if it’s more cost-effective to have the user enter the information manually or to use a software that can import data from a database. In this case, free software is no longer enough.

In some companies, the same employee handles the entire labelling process from creating the template to printing and applying the label. Then, using a standard design software may be totally justified.

In other companies, especially when there’s a lot of data, the printing of labels must be protected from possible errors. In this case, it is good to have a solution where a label template is prepared beforehand and the user can only fill in the necessary fields and send the label to the printer (for example Brady Print Partner). In an even safer solution, the user cannot modify the data and can only see the information coming from the database. The only responsibility of the employee is to select which labels to print (BarTender Forms, NiceLabel Powerforms).

In other companies, especially when there’s a lot of data, the printing of labels must be protected from possible errors. In this case, it is good to have a solution where a label template is prepared beforehand and the user can only fill in the necessary fields and send the label to the printer (for example Brady Print Partner). In an even safer solution, the user cannot modify the data and can only see the information coming from the database. The only responsibility of the employee is to select which labels to print (BarTender Forms, NiceLabel Powerforms).

These solutions are semi-automatic. The data moves between the database or ERP system and the labelling software automaticallly, but a human interaction is still needed: they open the corresponding software, choose the correct rows or enter the data, define the necessary quantities and print the labels. Sometimes it is wiser to exclude a person altogether. In a fully automatic solution the data moves between the ERP system and printer directly or the labelling software monitors a pre-defined folder and as soon as a file appears, the print job is sent to the printer. Nii väheneb eksimisvõimalus ja sellest tulenev kulu ettevõttele veelgi. This reduces the risk of errors and the resulting cost to the company even further.

It is possible, that a company finds the perfect labelling software, but fails to anticipate the changing needs in the near future (for example, swithing to a new ERP system that allows automated printing). Such occasions need to be considered at an early stage, because if you have a software that supports it, then it’s usually cheaper to buy an add-on (automation, larger number of printers etc.) than to start from scratch and throw the existing software in the trash.

Choosing a labelling software can be quite a long process, because there are a lot of aspects to consider. Hopefully, both this guide and our years of experience will help to make it a lot easier, so that the result is, if not the „right“ one, then at least the best possible solution so that the last piece of the puzzle will be in place.

Choosing a labelling software can be quite a long process, because there are a lot of aspects to consider. Hopefully, both this guide and our years of experience will help to make it a lot easier, so that the result is, if not the „right“ one, then at least the best possible solution so that the last piece of the puzzle will be in place.